Fundamentals of Thermodynamics: Exploring the basic concepts of enthalpy, entropy, and the laws of thermodynamics in refrigeration.

Thermodynamic Refrigeration Cycles: Understanding various refrigeration cycles and their applications in domestic systems.

State Changes in Thermodynamic Systems: Analyzing how refrigerants transition between different states in the refrigeration process.

Thermodynamic Property Diagrams: Learning to interpret and utilize key diagrams like T-v (temperature vs. specific volume), p-h (pressure vs. specific enthalpy), T-s (temperature vs. specific entropy), and h-s (specific enthalpy vs. specific entropy).

Pressure-Enthalpy (p-h) Diagrams: In-depth study of the most commonly used diagram in refrigeration, the pressure-enthalpy chart, and its practical applications.

Fluid Properties in Refrigeration: Examination of the properties of various refrigerants and their impact on refrigeration systems.

Basics of Refrigeration: Understanding the refrigeration cycle, key components, and the principles of heat transfer.

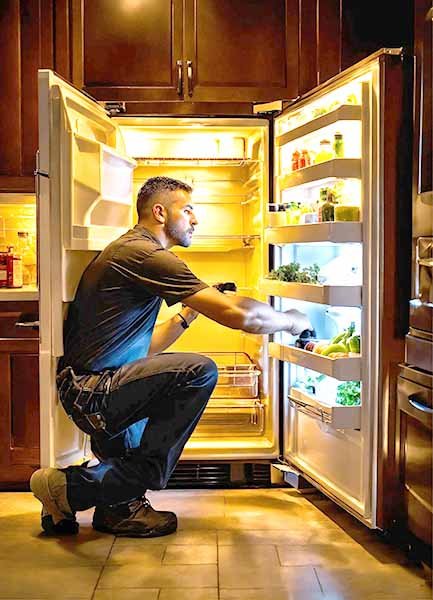

Household Refrigerators and Freezers: Hands-on training in maintenance, troubleshooting, and repair of domestic refrigerators and freezers.

Water Coolers and Dispensers: Detailed study of system design, temperature control, and maintaining hygiene standards.

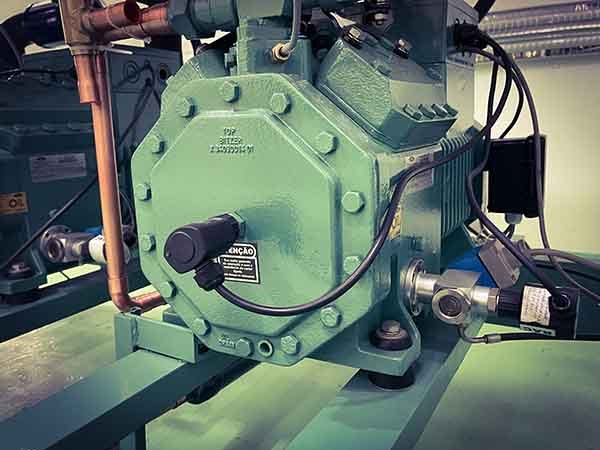

Compressor Technology: Exploring types of compressors, their functions, and maintenance in domestic units.

Refrigerants and Environmental Impact: Studying different refrigerants, their characteristics, and environmental considerations.

Electrical Fundamentals in Refrigeration: Learning about electrical components, circuits, and safety in refrigeration systems.

Evaporators and Condensers: Design, functionality, and maintenance of evaporators and condensers in household units.

Thermostat Controls and Calibration: Operating and calibrating thermostats for efficient temperature management.

Sealed System Repairs: Techniques for maintaining and repairing the sealed systems of refrigerators and freezers.

Defrost Mechanisms: Understanding different defrost systems used in domestic refrigeration.

Energy Efficiency in Refrigeration: Practices and technologies for enhancing energy efficiency in refrigerators and freezers.

Ventilation and Heat Exchange: Principles of ventilation and heat exchange in maintaining refrigerator efficiency.

Noise Diagnosis and Control: Identifying and addressing common noise issues in domestic refrigeration units.

Cooling Load Calculations: Methods for determining the cooling load requirements in refrigeration.

Insulation and Gasket Maintenance: Importance and maintenance of insulation and gaskets in refrigerators.

Lighting and Electrical Accessories: Maintenance of lighting and electrical components in refrigeration units.

Door Alignment and Seal Issues: Resolving common issues with door alignment and seals.

Smart Refrigeration Technologies: Overview of advanced technologies and IoT integration in modern refrigeration.

Diagnostic Tools and Techniques: Introduction to tools and techniques for diagnosing refrigeration systems.

Safety Standards and Protocols: Adhering to safety standards in refrigeration repair and maintenance.

Customer Service in Refrigeration: Developing customer service skills specific to the refrigeration industry.

Preventive Maintenance Practices: Comprehensive guide to preventive maintenance for extended unit life.

Troubleshooting Refrigeration Issues: Approaches to effectively troubleshoot common issues in refrigerators and freezers.

Retrofitting and Upgrading Refrigeration Systems: Processes and considerations for retrofitting and upgrading older refrigeration systems.

Introduction to Air Conditioning: Understanding the basics of air conditioning, including types of systems and their applications.

AC System Components: Detailed study of components like compressors, condensers, evaporators, and expansion devices in AC systems.

Air Conditioning Refrigerants: Exploring various refrigerants used in AC systems, focusing on characteristics and environmental impacts.

AC Electrical Systems: In-depth look at electrical components in AC systems, including motors, capacitors, and control circuits.

Psychrometrics in Air Conditioning: Studying the properties of air-vapor mixtures and their importance in air conditioning processes.

Load Calculation and System Sizing: Techniques for accurately calculating cooling loads and determining appropriate system sizing.

Duct Design and Air Distribution: Principles of ductwork design, sizing, and ensuring effective air distribution.

AC System Installation: Best practices for the installation of various types of air conditioning systems.

Thermostats and Control Systems: Understanding and working with different types of thermostats and modern control systems.

Indoor Air Quality (IAQ) in AC Systems: Addressing IAQ concerns, including ventilation, filtration, and humidity control.

Energy Conservation in Air Conditioning: Strategies and techniques for enhancing energy efficiency in AC systems.

Air Conditioning Maintenance: Comprehensive guidance on routine and preventative maintenance practices.

Troubleshooting AC Problems: Systematic approaches to diagnosing and resolving common AC issues.

Repair Techniques for AC Systems: Advanced repair methods and best practices for fixing AC systems.

Safety Protocols in AC Work: Emphasizing safety standards and protocols specific to air conditioning work.

Sustainable AC Practices: Exploring eco-friendly practices and green technologies in air conditioning.

Building Automation Systems: Introduction to building automation and its integration with AC systems.

Heat Pumps and Their Functionality: Detailed look at heat pump systems, including operation and maintenance.

Variable Refrigerant Flow (VRF) Systems: Understanding the operation and advantages of VRF systems in air conditioning.

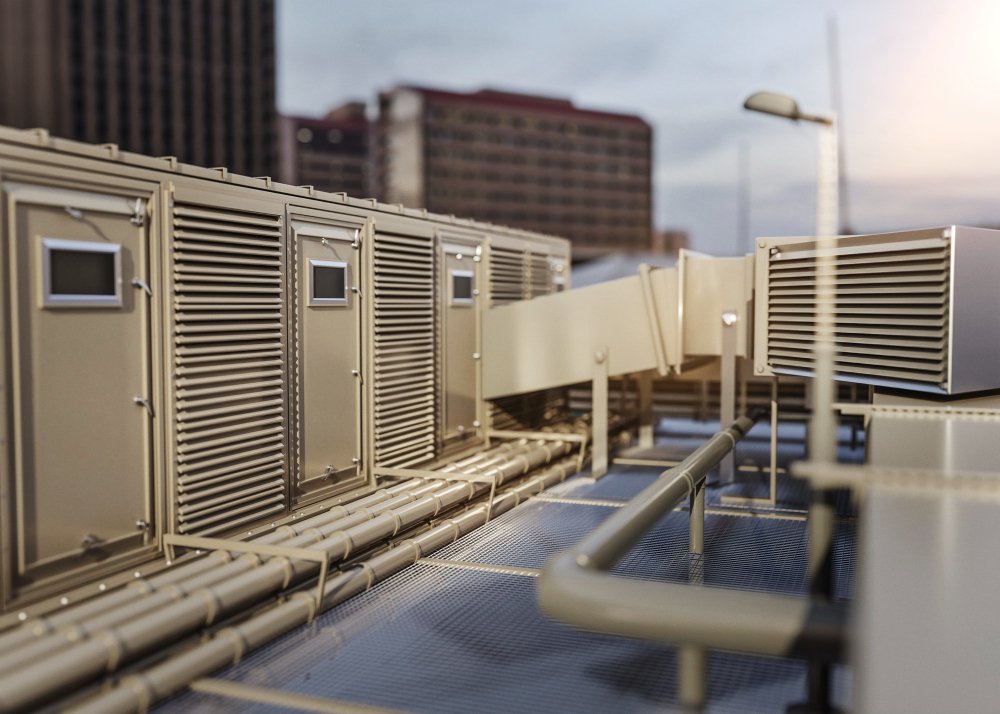

Chilled Water Systems: Examining the design and operation of chilled water systems used in larger buildings.

AC System Retrofitting: Processes and considerations for retrofitting and upgrading existing AC systems.

Customer Service in AC Maintenance: Developing effective communication and customer service skills for AC technicians.

AC System Diagnostics: Using advanced diagnostic tools and techniques for AC system analysis.

Noise Control in AC Systems: Identifying and addressing noise issues in air conditioning units.

Environmental Regulations and Compliance: Overview of environmental regulations impacting AC systems, including refrigerant handling.

Commercial and Industrial AC Systems: Differences between residential and larger-scale commercial/industrial systems.

Smart AC Technologies: Exploring advancements in smart technology for air conditioning, including IoT integration.

AC System Efficiency Analysis: Techniques for evaluating and enhancing the efficiency of air conditioning systems.

Emergency AC Services and Protocols: Training for handling emergency service calls and urgent AC issues.

Professional Development in the AC Industry: Focusing on career advancement and staying updated with industry trends.

Overview of Commercial Refrigeration: Introduction to the world of commercial refrigeration and its industry applications.

Types of Commercial Refrigeration Systems: Exploring various systems including walk-ins, display cases, and industrial chillers.

Refrigeration System Design Principles: Fundamentals of designing efficient and reliable commercial refrigeration systems.

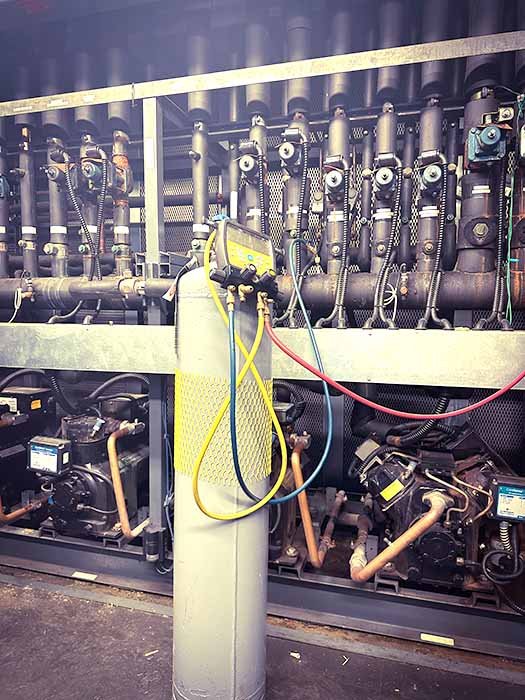

Advanced Compressor Technology: In-depth study of compressors used in commercial settings, including screw and centrifugal types.

Evaporators in Commercial Systems: Understanding the design and functionality of evaporators in large-scale refrigeration.

Condenser Units for Commercial Use: Examining different types of condensers and their application in commercial refrigeration.

Commercial Refrigerants: Focus on refrigerants used in commercial applications, including natural and synthetic options.

Thermostatic Expansion Valves (TXVs): Detailed study of TXVs and their role in commercial refrigeration systems.

Pressure Controls and Monitoring: Learning about pressure control mechanisms and their importance in commercial refrigeration.

Electrical Systems in Commercial Refrigeration: Comprehensive look at the electrical components and wiring in commercial refrigeration systems.

Commercial Refrigeration Load Calculations: Methods for accurately determining the refrigeration load for commercial applications.

Refrigeration Cycle in Commercial Systems: In-depth exploration of the refrigeration cycle as it applies to commercial refrigeration.

Piping and Insulation: Best practices for piping and insulation in commercial refrigeration systems.

Defrosting Mechanisms: Understanding different defrosting methods used in commercial refrigeration.

Energy Efficiency in Commercial Refrigeration: Strategies for maximizing energy efficiency in commercial systems.

Maintenance of Commercial Refrigeration Systems: Routine and preventive maintenance practices for commercial refrigeration.

Troubleshooting Commercial Systems: Approaches to diagnosing and resolving issues in commercial refrigeration units.

Repair Techniques for Commercial Refrigeration: Advanced repair methods for commercial refrigeration systems.

Safety Protocols in Commercial Refrigeration: Emphasizing safety measures and protocols in the commercial refrigeration industry.

Control Systems and Automation: Studying automated control systems used in modern commercial refrigeration.

Commercial Refrigeration System Retrofitting: Retrofitting processes for updating and upgrading existing commercial systems.

Environmental Impact of Commercial Refrigeration: Discussion on the ecological footprint of commercial refrigeration and ways to minimize it.

Regulations and Compliance: Overview of regulations and compliance standards in commercial refrigeration.

Heat Rejection in Commercial Systems: Understanding heat rejection processes in large refrigeration systems.

Humidity Control in Commercial Refrigeration: Techniques for managing humidity levels in commercial refrigeration spaces.

Case Studies in Commercial Refrigeration: Analysis of real-world examples and case studies in commercial refrigeration.

Customer Service and Communication: Skills for effective customer service and communication in the commercial sector.

Commercial System Diagnostics: Using advanced diagnostics tools for commercial refrigeration systems.

Sound Management in Commercial Units: Addressing noise control in commercial refrigeration systems.

Commercial Refrigeration for Food Preservation: Specific requirements for food preservation in commercial refrigeration.

Industrial Ice Machines: Operation and maintenance of industrial-scale ice machines.

Blast Freezers and Chillers: Studying the operation and application of blast freezers and chillers.

Ammonia Refrigeration Systems: Specialized training on ammonia-based refrigeration systems, their properties, and safety measures.

CO2 Refrigeration Systems: Understanding the use and advantages of CO2 in commercial refrigeration.

Supermarket Refrigeration Systems: Specific needs and solutions for refrigeration in supermarket settings.

Transport Refrigeration: The intricacies of refrigeration systems used in transportation.

Cold Storage Warehousing: Principles and practices of managing large-scale cold storage facilities.

Refrigeration System Controls and Sensors: Deep dive into controls and sensors used for monitoring and managing commercial refrigeration.

Commercial System Efficiency Analysis: Methods for assessing and improving the efficiency of commercial refrigeration systems.

Emergency Services in Commercial Refrigeration: Training for responding to and managing emergency situations in commercial refrigeration.

Sustainability Practices in Commercial Refrigeration: Exploring sustainable practices and technologies in the commercial sector.

Quality Assurance in Commercial Refrigeration: Ensuring quality and reliability in commercial refrigeration services.

Project Management for Commercial Installations: Skills and strategies for effective project management in commercial refrigeration installations.

Advanced Refrigeration Technologies: Keeping up with the latest technological advancements in commercial refrigeration.

Financial Management for Refrigeration Projects: Understanding the financial aspects of managing commercial refrigeration projects.

Advanced Cold Chain Management: Delve into the complexities of cold chain management for commercial refrigeration. This includes logistics planning, temperature monitoring, and ensuring compliance with health and safety standards for perishable goods storage and transport.

Custom Refrigeration Solutions for Unique Applications: Tailoring refrigeration systems for specific commercial needs, such as specialized cold storage, wine cellars, or pharmaceutical refrigeration. Understand the unique challenges and solutions for these bespoke applications.

Emerging Trends in Commercial Refrigeration: Stay ahead in the industry by exploring emerging trends and innovations in commercial refrigeration, such as IoT integration, environmentally-friendly refrigerants, and AI-powered monitoring systems.

Energy Audits and Sustainability Reporting: Learn to conduct energy audits for commercial refrigeration systems, identify areas for energy savings, and prepare sustainability reports for businesses focusing on eco-friendly practices.

Workplace Health and Safety Standards: Comprehensive training on workplace health and safety specific to commercial refrigeration, including risk assessment, safe handling of refrigerants, and emergency response protocols.

Financial Incentives and Rebates for Energy-Efficient Systems: Understanding the financial incentives, including rebates and tax credits, available for businesses that invest in energy-efficient commercial refrigeration systems.

Building Client Relationships and Retention: Strategies for building long-term client relationships in the commercial refrigeration sector, focusing on customer service, follow-up practices, and managing client feedback effectively.

Refrigeration System Commissioning and Decommissioning: Detailed process of commissioning new refrigeration systems and decommissioning old ones, including environmental considerations for refrigerant recovery and system disposal.

Ammonia and CO2 Systems: In-depth exploration of ammonia and carbon dioxide refrigeration systems, focusing on their unique properties, handling, and safety measures.

System Design and Operations: Training in designing and operating large-scale industrial refrigeration systems, with an emphasis on efficiency and automation.

Troubleshooting and Risk Management: Developing skills for problem-solving and risk assessment in complex industrial refrigeration contexts.

Compressor Technology in Industrial Systems: Study of advanced compressor types used in industrial refrigeration, including screw, reciprocating, and centrifugal models.

Advanced Control Systems: Understanding the sophisticated control systems used in industrial refrigeration for monitoring and optimizing performance.

Energy Management in Industrial Refrigeration: Strategies and techniques for energy conservation and management in large-scale refrigeration systems.

Industrial Refrigeration Safety Standards: Comprehensive overview of safety standards and protocols specific to industrial refrigeration.

Piping and Valve Design: Detailed study of piping systems and valve design in industrial refrigeration, focusing on optimal flow and efficiency.

Heat Exchanger Technology: Exploring the various types of heat exchangers used in industrial settings and their maintenance.

Industrial Refrigerants and Environmental Compliance: Deep dive into the types of refrigerants used in industrial systems and their environmental impacts.

Psychrometrics in Industrial Applications: Application of psychrometric principles in industrial refrigeration for precise climate control.

Defrosting Systems in Industrial Refrigeration: Understanding different defrosting methods and their application in large-scale systems.

Industrial Cooling Towers: Study of cooling tower design, operation, and maintenance in industrial refrigeration systems.

Evaporative Condensers: Focusing on the design, operation, and maintenance of evaporative condensers in industrial settings.

Vibration Analysis and Noise Control: Techniques for analyzing vibrations and controlling noise in industrial refrigeration equipment.

Automation and IoT in Industrial Refrigeration: Integrating automation and Internet of Things (IoT) technologies for smart industrial refrigeration management.

Load Calculation for Industrial Applications: Methods for calculating cooling loads specific to industrial refrigeration requirements.

Preventive Maintenance Strategies: Developing effective preventive maintenance schedules for industrial refrigeration systems.

Industrial Refrigeration Project Management: Skills and strategies for managing large-scale industrial refrigeration projects.

Insulation and Energy Loss Prevention: Techniques for insulation and preventing energy loss in industrial refrigeration systems.

Advanced Refrigeration Cycle Analysis: In-depth analysis of refrigeration cycles and their optimization in industrial settings.

Emergency Response Planning in Industrial Refrigeration: Preparing for and managing emergency situations in industrial refrigeration contexts.

Industrial System Retrofitting and Upgrades: Processes and considerations for retrofitting and upgrading existing industrial refrigeration systems.

Regulatory Compliance in Industrial Refrigeration: Navigating the regulatory landscape, including environmental and safety regulations relevant to industrial refrigeration.

Sustainability Practices in Industrial Refrigeration: Exploring sustainable and eco-friendly practices in industrial refrigeration operations.

Advanced Diagnostics for Industrial Systems: Utilizing advanced diagnostic tools and techniques for troubleshooting industrial refrigeration systems.

Fluid Dynamics in Industrial Refrigeration: Understanding the principles of fluid dynamics as applied to the movement of refrigerants in industrial systems.

Cost Analysis and Budgeting: Techniques for cost analysis and budgeting in the management of industrial refrigeration projects.

Cold Storage Warehouse Management: Principles and practices of managing large-scale cold storage facilities in industrial contexts.

Custom Refrigeration Solutions for Industry-Specific Needs: Tailoring refrigeration systems for specific industrial applications.

Thermal Storage Systems: Studying the use and benefits of thermal storage systems in industrial refrigeration.

Risk Assessment and Hazard Analysis: Conducting risk assessments and hazard analysis for safe operation of industrial refrigeration systems.

Business Acumen for Industrial Refrigeration Professionals: Developing business skills specific to the industrial refrigeration sector.

Industrial Refrigeration System Commissioning and Decommissioning: Procedures for commissioning new systems and safely decommissioning old ones.

Quality Assurance and Control in Industrial Refrigeration: Ensuring and maintaining quality standards in industrial refrigeration services.

Refrigerant Recovery and Recycling: Best practices for refrigerant recovery and recycling in industrial systems.

Customer Relationship Management in Industrial Settings: Building and maintaining strong customer relationships in the industrial refrigeration market.

Advanced Leak Detection Techniques: Mastering advanced techniques for detecting refrigerant leaks in industrial systems.

Human Factors in Industrial Refrigeration Operation: Understanding the impact of human factors on the operation and maintenance of industrial refrigeration systems.

Career Development and Continuing Education: Opportunities for career advancement and ongoing education in the field of industrial refrigeration.

This comprehensive curriculum for Module 4: Industrial Refrigeration is designed to provide specialized training for technicians to excel in the industrial refrigeration sector, covering technical, safety, environmental, and business aspects of the industry.

Revolutionizing Refrigeration Education

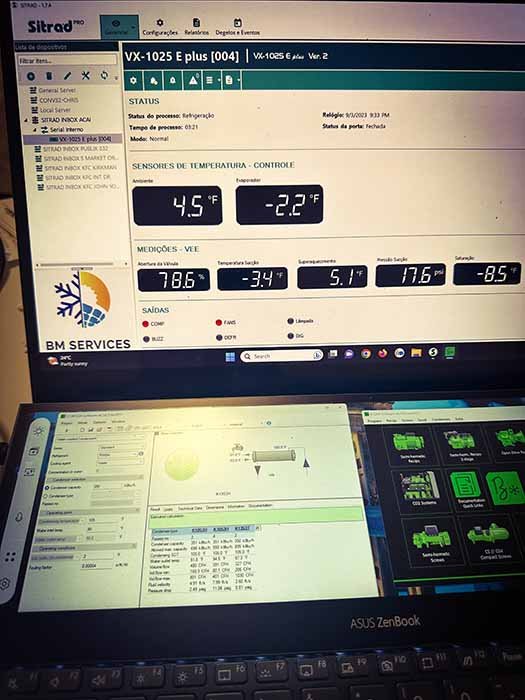

We are thrilled to announce our partnership with Full Gauge Controls, a renowned leader in the field of refrigeration, heating, and pool system controllers. This collaboration brings an exciting dimension to our training program, providing our students with hands-on experience using some of the best controllers in the market.

Innovative Learning with State-of-the-Art Equipment

Full Gauge Controls specializes in developing cutting-edge control systems that are integral to modern refrigeration and HVAC applications. Their products stand at the forefront of technology, offering precision, reliability, and ease of use. This partnership allows us to equip our classrooms with these advanced controllers, giving our students the invaluable opportunity to train with the same high-quality equipment they will encounter in the field.

Real-World Application and Industry Relevance

Our collaboration with Full Gauge Controls is not just about access to superior technology; it’s about enhancing the real-world relevance of our training. Students will learn to program, operate, and troubleshoot using controllers that are widely used in the industry. This experience is crucial in preparing them for successful careers, as it bridges the gap between theoretical knowledge and practical skills.

Expanding Horizons in Refrigeration and HVAC Training

Full Gauge Controls’ diverse range of products, encompassing refrigeration, heating, and pool systems, means that our students will gain a broad and versatile skill set. This versatility is vital in today’s dynamic job market, where the ability to handle a range of systems is a significant advantage.

Join Us for a Future in Cutting-Edge Refrigeration and HVAC Technologies

We invite you to be part of this exciting journey in refrigeration and HVAC education. Whether you are starting a new career or looking to upgrade your skills, our partnership with Full Gauge Controls is your pathway to becoming a proficient professional in the industry. Experience the best in refrigeration training with BM Services USA and Full Gauge Controls – where innovative technology meets practical, hands-on learning.

Empowering the Future of Refrigeration and HVAC with Bitzer Compressors

We are excited to announce our partnership with Bitzer Compressors, a global leader in the refrigeration and air conditioning industry. This collaboration marks a significant milestone for our Industrial Refrigeration Training Program, bringing real-world applications and cutting-edge technology directly to our students.

Why Bitzer Stands Out

Comprehensive Product Range: Bitzer’s extensive lineup of compressors, including reciprocating, screw, and scroll types, allows us to offer practical training across a broad spectrum of applications. From commercial food preservation to complex building air conditioning systems, our students gain hands-on experience with industry-standard equipment.

Unmatched Quality and Reliability: Bitzer’s commitment to quality is evident in every compressor they produce. Their reputation for reliable and long-lasting products means our students learn with equipment that sets the standard in the industry, rivaling well-known brands like Carrier, York, and Trane.

Innovative Design for High Reliability: The Bitzer screw compressors, known for their fewer parts and minimal wear, offer an excellent model for teaching about durability and consistent performance in industrial settings.

Focus on Energy Efficiency: In an era where energy efficiency is paramount, Bitzer’s products like the ORBIT 6 and 20 hp scroll compressors provide our students with insights into designing and operating systems that reduce operational costs and contribute to environmental sustainability.

Join Us in This Revolutionary Journey

Our partnership with Bitzer Compressors is more than just an educational collaboration; it’s a commitment to shaping the future of the refrigeration and HVAC industry. By integrating Bitzer’s state-of-the-art compressors into our curriculum, we offer our students an unparalleled opportunity to learn from the best in the business. Whether you’re starting a new career or advancing in the field, join us at the forefront of refrigeration and HVAC technology and be part of the next generation of industry leaders.

Experience the synergy of top-notch education and world-class equipment with BM Services USA and Bitzer Compressors – where innovation meets practical training.